The 2020s mark the start of the Century of Biology and engineered biology will be the key science unlocking some of the most wide-spanning and impactful discoveries for human and planetary health.

The realm of biology looks far more different nowadays than it looked a decade ago — the convergence of bits and atoms has brought science much closer to systematic engineering than the randomised, discovery-based approach that characterised the industry so far. The drastic reduction in the cost of gene sequencing and synthesis, the orders’ of magnitude increase in data generation, and the penetration of computer science, AI and LLM are among the core drivers of this paradigm shift. Treating biology as code enables researchers worldwide to significantly improve the speed and quality of experimentations, giving more shots on goals and pushing the boundaries of what’s possible to achieve with biology. However, no matter how much further computational biology and in silico analysis progress, biology is still inherently linked to the physical realm: wet lab experimentation is necessary for data generation, hypothesis testing and complex structures exploration.

Since our investment in Seqera, the global leader in bioinformatics software, we knew that the progress on the dry-lab side needs to go hand in hand with progress on the wet-lab side — running experiments cheaply, reproducibly and automatically is the key to kickstart and continue innovation in biology and pharma.

One year ago, we were lucky enough to meet Jimmy, Mark and the team at Monomer Bio, and we were impressed by the founders’ complimentary backgrounds across biology, robotics, and AI; the product-focused approach tackling living cell cultures; and the traction across Research Institutes, Biotech and Big Pharma. Today, we are excited to announce we are leading Monomer’s $5.6M Seed round alongside LifeX, Notley Ventures, and prominent angel investors, including Kevin Mahaffey, co-founder of Lookout, and Amit Gupta, a former executive at Benchling.

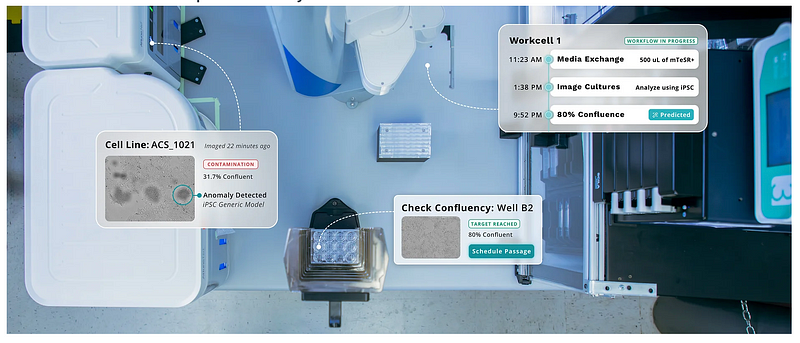

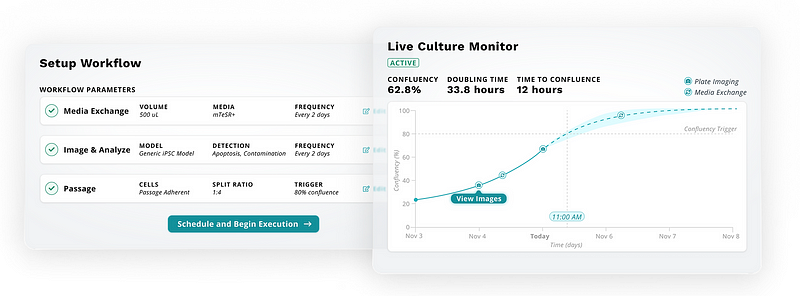

Based in San Francisco, Monomer develops software for automating cell culture and cell engineering experiments. By tightly bundling experiment execution and data management, Monomer provides a decision-making system for scientists, based on a real-time feed of analysed culture data collected in the background while scientists focus on designing experiments and running biology. Its software can 10x cell-culture throughput and 1000x the speed of creating automated optimisation protocols. By enabling autonomous cell culture and collecting prime experiment data, Monomer is rapidly becoming the de-facto Operating System for wet-lab-driven experimentation, bringing advanced AI/ML capabilities to analytics and manufacturing workflows in biotech and pharma.

We are excited to embark on this journey with the Monomer team and here are a few core reasons why.

Living cell lab automation will underpin the third innovation wave in biotech

What drove us towards beginning to research the lab automation space as part of our Open Science Software Infrastructure thesis is the belief that cheap, fast, and reliable data generation is key to unlocking the next gains for biopharma. Robotics and ML advances have made it possible for scientists to dream of conducting wet lab experiments without manual intervention, yet automation is still nowhere near industries like logistics and manufacturing. Imagine the speed of innovation biology could have if a researcher had access to twenty robots, rather than twenty researchers having to share a single robot! With costs of bringing drugs to markets at an all-time high and biopharma’s IRR on R&D spend at an all-time low, there is a huge opportunity for the right product that can enhance the scientific yield of assets while reducing costs — which is where Monomer comes into play.

Monomer supercharges cell engineering. Cells are orders of magnitude more complex than small molecules or biologics, and require researchers to conduct manual, multi-day and iterative experiments that more often than not involve working over the weekend. Pharma is moving away from small molecules, and modalities such as Car-T, Stem, RNA and gene therapy are amongst the fastest growing R&D centres, taking up to 50% of all biopharma drug pipelines. Yet, manual work still contributes to around 25% of costs, and automation is seen as the key driver to drastically reduce CoGS, deviations in manufacturing and even decentralised production.

If we are to cure some of the most dreadful diseases on this planet, we need to increase the scientific yield of biopharma’s R&D experiments. That will require orders of magnitude increases in data generation, speed, and accuracy across R&D and manufacturing, which can only be enabled by combining lab automation with AI-driven applications. Starting with cell engineering, Monomer Bio is building the underlying infrastructure to enable scientists to move forward with biopharma’s most impactful discovery at an unprecedented speed and cost.

Built for Scientists, by Scientists

Lab automation is not new to innovation — started with hardware vendors such as Illumina, Tecan or Hamilton in the 1970–80s, then evolved with the first wave of scheduling and orchestrating software vendors (e.g. HighRes Biosolution or Biosero) from around the early 2000s. The 2010s saw a third wave of innovation with the rise of Cloud Lab companies such as StrateOS or Emerald Cloud Lab, which developed their proprietary middleware to provide remote lab services.

We are now upon the fourth innovation wave in Lab Automation — while equipment quality has improved significantly and costs have decreased drastically, thanks to innovators such as OpenTrons, Thermofisher and Hamilton, there still is a disconnect between each piece of equipment, their orchestration and the cloud-based analysis researchers conduct on their data — which inhibits the possibility to benefit from Machine Learning advances to speed up scientific discovery. Companies like Monomer, innovating in the middle layer between equipment-level data generation and analytics, are best placed to build the next R&D Operating System focused on prime data generation.

The vast majority of companies innovating in the lab automation space have historically aimed to cater for most use cases and workflows. Monomer’s uniqueness lies in its focused approach towards a single, scientific use case: living cell cultures work-cells. The company solves day-to-day workflow problems for scientists, such as enabling them to count cell lines, monitor confluence, passage cells and even terminate cultures remotely. Those are critical workflows that are closely linked to an asset moving along the therapy pipeline, yet qualified PhD-level scientists spend several hours a day conducting them manually. Scientists will continue being the most important node within biopharma and companies that focus on empowering them by tackling specific use cases have the greatest chances of success in this industry. Monomer’s automation software enables scientists to run complex experiments autonomously and focus on critical design of experiments, while running all cell-engineering development, optimisation, analytics and manufacturing on Monomer’s AI-driven application — increasing the speed and success of key assets and enhancing the scientific yield of biopharma’s R&D dollars.

The complexity and uniqueness of biology as a field call for the most successful products to be built by scientists, for scientists. Jimmy and Mark, the company’s founders, have the perfect cross-disciplinary skill set to build a company in this space: Jimmy was on the founding team at Transcriptic (now StrateOS, the world’s first robotic cloud lab) and Mark was an early employee at Kensho and built biotech tools at Chan Zuckerberg Initiative. The team has also already attracted experienced team members from Strateos and Benchling. We are proud to work alongside this team on its mission to build the standard operating system for the biology lab, where all cell-line development, optimisation, and analytics workflows, all the way to manufacturing will happen in the near future.

We are seeing the emergence of a new category of companies forming the infrastructure layer for the future of science, a future that is engineering-based, data-driven and Open — where bench scientists and bioinformaticians collaborate symbiotically through in silico and in vivo experimentation.

We couldn’t be more excited to partner with Monomer Bio and support Jimmy, Mark and the team on their journey to become the Operating System for wet-lab-driven experimentation, bringing advanced AI/ML capabilities to analytics and manufacturing workflows in biotech and pharma.